ALUMINUM BRONZE CASTING

Aluminum Bronze Alloy

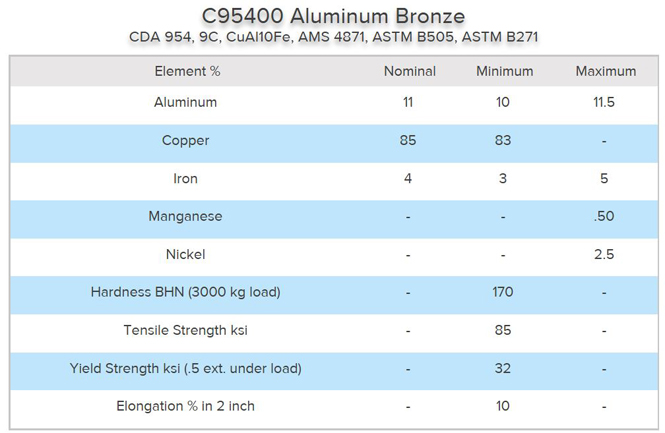

Aluminum bronze alloys are used for their combination of high strength and excellent corrosion and wear resistance. C95400 aluminum bronze is a popular cast aluminum bronze with high-strength properties and excellent resistance to wear and corrosion. Although this alloy is supplied in the cast condition, it can be heat-treated to enhance its mechanical properties for more demanding applications.

Applications for Aluminum Bronze

Aluminum bronze alloys are used in marine hardware, shafts, and pump and valve components for handling seawater, sour mine waters, non-oxidizing acids, and industrial process fluids. They are also used in applications such as heavy duty sleeve bearings and machine tool ways. Aluminum bronze castings have exceptional corrosion resistance, high strength, toughness, and wear resistance. Not to mention their good casting and welding characteristics.

Aluminum Bronze Alloy Product Selection

NFL14706 Aluminum Bronze Copper Nickel Aluminum, 2.0978, DIN 17665, UA11N, CuAl11Ni5Fe5

NFL14706 is an excellent choice for its application on aeronautical industry, due to its high mechanical properties and oxidation resistance. NFL14706 is resistant to corrosion in saline mist area.

Typical Uses for NFL14706 Aircraft Bronze:

AEROSPACE: Landing Gear Bushings & Bearings, Guides, Nuts

HEAVY INDUSTRY: Civil engineering, iron and steel industry, manufacturing guides, rolling mills

C95900 Aluminum Bronze is characterized by its high strength and excellent corrosion resistance. This alloy is for heavier loads under abrasive conditions where impact is present. C95900 is an excellent heavy duty bearing alloy, and should be used against hardened steel shafts, with both shaft and bearing machined to fine surface finishes.

Uses for CDA 959åÊis utilized in the tool and die and roll forming industries, and its applications include a variety of heavy duty mechanical and structural products including gears, worm drives, valve guides and seats.

C95400 Aluminum Bronze, also known by C954, is the most popular, all purpose aluminum bronze alloy. It provides high yield and tensile strength, good ductility, weldability and exceptional resistance to wear, fatigue and deformation under shock or overload.

Typical applications include bearings, gears, valve components, wearplate and wearstrip. Conforms to continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

C61800 is an aluminum bronze containing nominally 89% copper, 10% aluminum and 1% iron. It has moderate strength, moderate ductility and can be hot worked or cold worked successfully. It has good resistance to corrosion in many environments.

Its numerous uses include bushings, bearings, corrosion-resistant components and welding rod