NICKEL ALUMINUM BRONZE CASTING

Nickel Aluminum Bronze Alloys

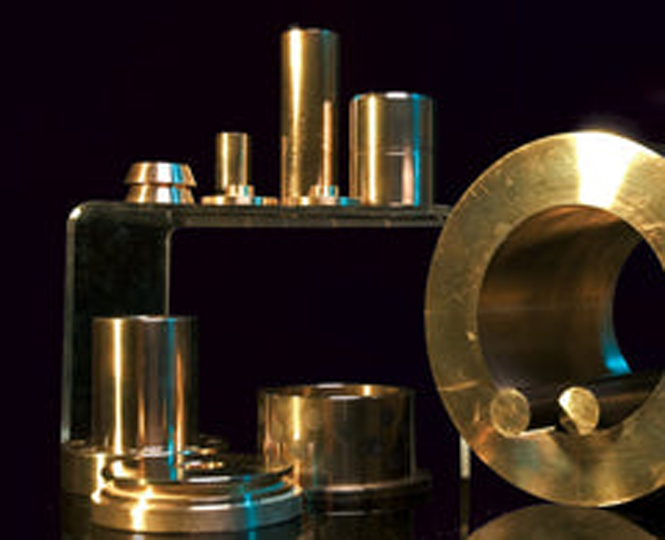

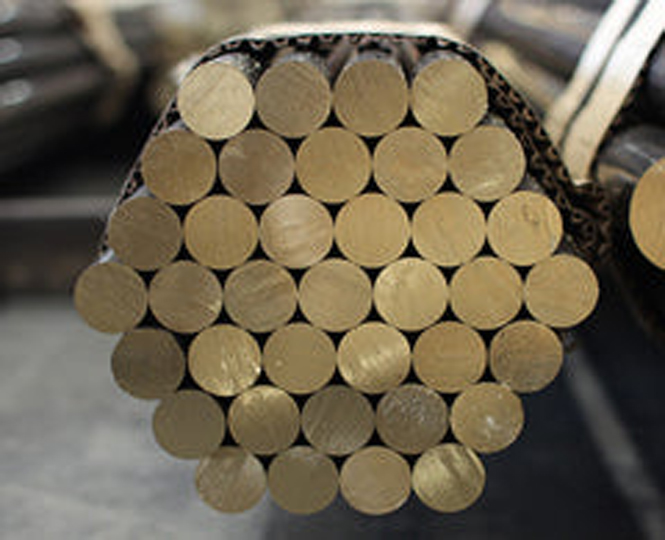

Nickel aluminum bronze alloys contain 5 to 11 percent aluminum, as well as additions of iron and nickel for strength. Increasing the aluminum content of bronze results in higher strength. These nickel aluminum bronze alloys are used for bushings, bearings, wear plates, and hydraulic valve components. Nickel aluminum bronze is available in rod, tube, and plate forms.

Applications for Nickel Aluminum Bronze

The various types of nickel aluminum bronze alloys are a popular choice for industrial applications such as landing gear bushings and bearings for the aerospace industry, propeller hubs, wear rings, and hardware for the marine industry, a piping for vertical pump columns, firefighting and fire suppression systems, and seawater lift pumps for the oil and gas industry, hydraulic bushings for earth moving equipment, as well as many other applications. This is due specifically to the addition of nickel which improves the corrosion resistance of the already versatile aluminum bronze alloys. Iron acts as a grain refiner and increases tensile strength without diminishing its excellent ductility and toughness.

Nickel Aluminum Bronze offers high ductility, high electrical and thermal conductivity, high impact strength, good creep resistance, ease of welding, and low volatility under high vacuum.

INDUSTRIAL: Bearings, Bushings, Valve Balls, Forming Dies for Roll Bearings, Hydraulic Bushings for Earth Moving Equipment, Valve Parts - Cryogenic

AMS 4640 Nickel Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance.

INDUSTRIAL: Hydraulic Bushings for Earth Moving Equipment, Corrosion Resistant Articles, Heat Exchanger Flanges, Heat Exchanger Headers, Tanks, Valve Balls, Structural Members, Pump Shafts, Valve Guides, Plunger Tips, Welded Piping Systems, Balls, Gears, Cams, Pump Parts, Shafting, Condenser Tube for Power Stations and Desalting Units, Valve Seats

AMS 4880 Nickel Aluminum Bronze is one of the most popular landing gear bushing materials specified today along with AMS 4640 material. NBM's brand of AMS 4880 is continuous cast and heat treated. Our AMS 4880 has outstanding mechanical properties and typically exceeds those of AMS 4640. In many cases NBM's AMS 4880 can be substituted for AMS 4640 with the advantage of our material being available in hollow bar, which provides for great cost savings due to weight reductions and a huge elimination of scrap. We can also supply rough machined blanks in this alloy, which helps to reduce scrap issues even further. Please send us your drawings.

Typical Uses for AMS 4880 Nickel Aluminum Bronze:

AEROSPACE: Landing Gear Bushings & Bearings, Valve Guides, Stems, Seats

INDUSTRIAL: Corrosion Resistant Parts, Wear Rings, Machine Tool Parts, Piston Guides, Worm Wheels, Hot Mill Gurdes

MARINE: Propeller Hubs, Wear Rings, Hardware, Worm Gears, Shafts, Sleeves

A special heat treatment process improves mechanical properties and strength-weight ratio beyond the range of commercial aluminum bronzes. For applications involving heavy loads, abrasive wear, friction, deformation and high temperatures.

C63000 (AMS 4640 - CDA 630) Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance. Typical applications for C63000 nickel aluminum bronze included aircraft landing gear components, strut bearings, main pistons, trunnion bearings and similar vital components.

AMS 4881 is offered in solid and hollow bars. The additional heat treating process improves mechanical properties and the strength to weight ratio exceeding the range of typical aluminum bronzes.

AMS 4881 is commonly used in applications involving heavy loads abrasion, friction, and deformation at high temperatures. In many cases AMS 4881 can replace AMS 4590/C63020 with the advantage of this material being available in tube form, which provides economic cost savings to you the customer.