NICKEL TIN BRONZE CASTING

Nickel Tin Bronze

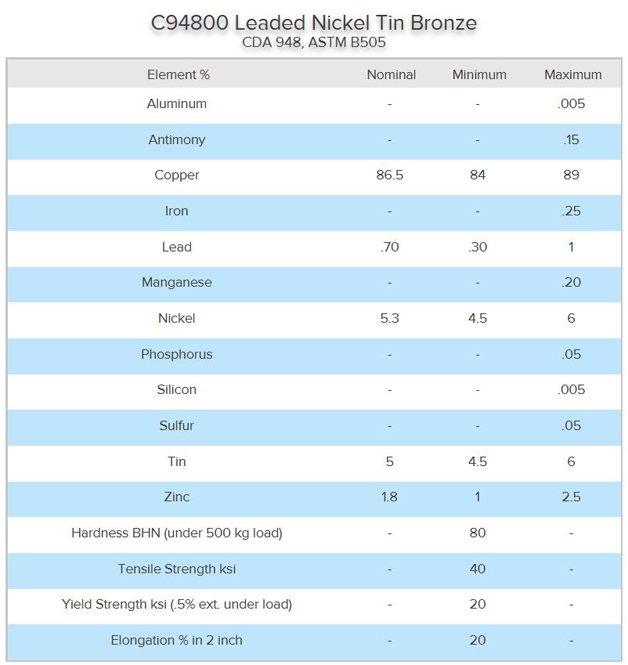

We offer Nickel tin bronze, including leaded, nickel gear, and “spinodal” bronzes. Common applications include worm wheels, worm gears, cams, pump bodies, and more. Take a look at all of our nickel tin bronze products here!

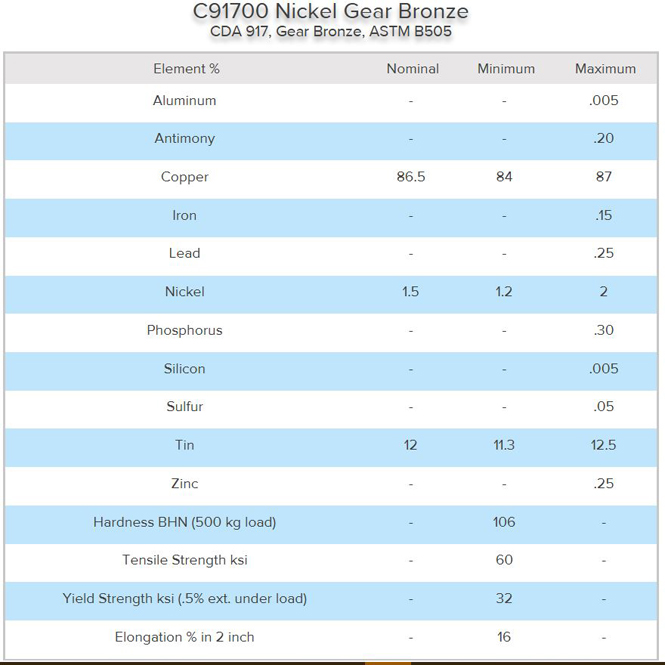

Typical Uses for C91700 Nickel Tin Bronze (Nickel Gear Bronze):

INDUSTRIAL: Worm Wheels, Worm Gears, Conprise Gears, Heavy Load, Relatively Low Speed Bearings

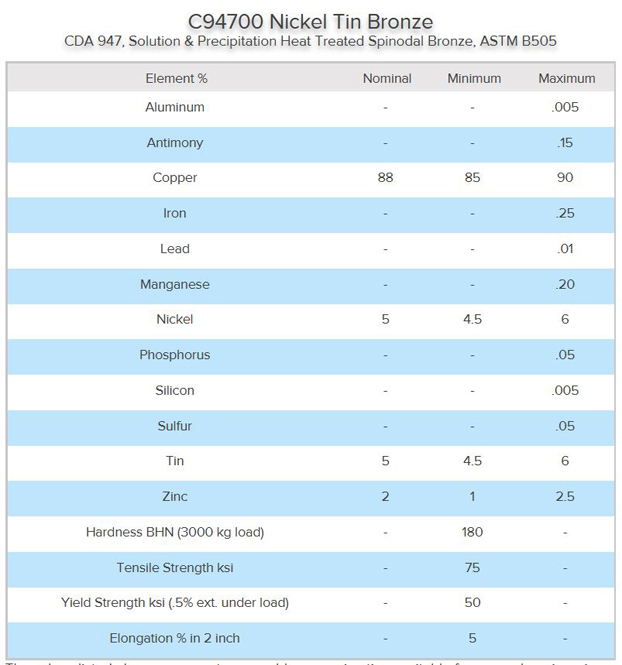

C94700 Nickel Tin Bronze "Spinodal"

Typical Uses for C94700 Nickel Tin Bronze "Spinodal":

INDUSTRIAL: Feeding Mechanisms, Gears, Shift Forks, Piston Cylinders, Wear Guides, Valve Components, Bearings, Nozzles

C96900 Nickel Tin Bronze (Spinodal Bearing & Bushing Bronze Systems)

This is a high-performance alloy which can withstand high loads and operate under severe conditions. An excellent low friction, non-corrosive bronze alloy now available from our inventory.

Nickel alloys contain several beneficial properties, such as heat and corrosion resistance, which make them ideal for high-temperature environments. A wide range of alloy combinations offer versatility—nuclear power and electrical industries often use these metals in steam and aircraft turbine manufacturing, but they also have many practical uses across other industries.

We have an abundant selection of nickel alloys at Wieland Diversified. From Nickel 400 to Hastelloy X, our diverse product line is designed for your custom requirements. Each alloy contains a different nickel concentration, which affects the composition’s properties. This adaptability allows you to use these alloys in various environments and temperature conditions.