COPPER NICKEL CASTING

Copper Nickel Alloy

Copper nickel alloys, also known as Cu-Ni, offers excellent corrosion resistance, especially in marine salt water environments. Copper nickel alloys that are generally chosen for sea water parts and service equipment contains 10 to 30 percent nickel.

We stocks C70600 and C71500 Copper Nickel pipes, which are commonly used in seawater piping due to its complete resistance to barnacles. Due to Its resistance of various sea organisms, this alloy makes seawater desalination, water systems, fire fighting systems, and similar applications very reliable.

These various alloys also have important additions of iron and manganese, which are necessary to maintain good corrosion resistance in the harsh environments. Aside from being very corrosion resistant to sea water, copper nickel alloys are very thermally stable. Copper nickel is most commonly used in applications such as electrical and electronic products, tubes for condensers in ships and power plants, various marine products, including valves, pumps, fittings, and sheathing for ship hulls.

APPLICATIONS Marine hardware Desalination Seawater piping systems Cooling loops Pipe nipples Copper Nickel Alloy Product Selection

Nickel silver bronze are alloys that contain copper, tin, lead, nickel, and zinc. Nickel silver bronze has low to moderate strength and good corrosion resistance and are named for their silvery luster.

They are used in the food and beverage handling equipment, decorative hardware, electroplated table ware, optical and photographic equipment and musical instruments.

We offer Nickel tin bronze, including leaded, nickel gear, and “spinodal” bronzes. Common applications include worm wheels, worm gears, cams, pump bodies, and more. Take a look at all of our nickel tin bronze products here!

C70600 (C706) & C71500 (C715), Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some of the primary uses for C706 include copper nickel fittings (CuNi Fittings) as well as condensers and exchanger shells.

C70600 & C71500, Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, and pump components.

Offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

CuNi10Fe1Mn, Copper nickel also has important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

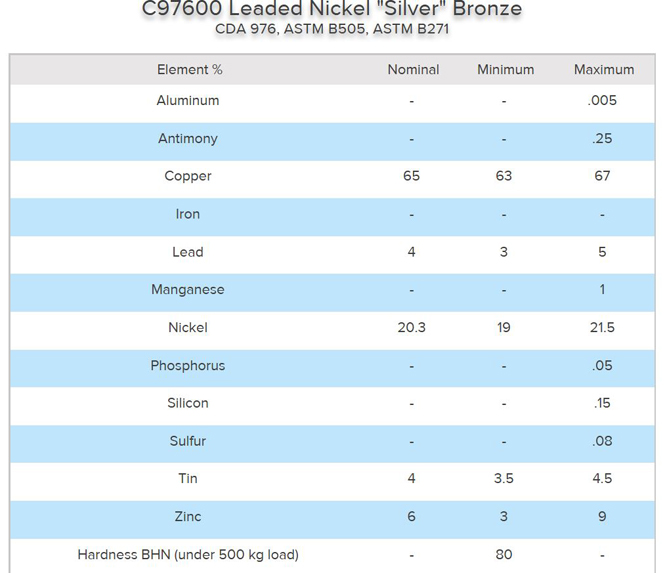

C97600 Nickel Silver Bronze, also referred to as dairy metal or dairy bronze, is a cast bronze alloy with a high machinability rating of 70. C976 Dairy Bronze contains 63-67% Cu, 3.5-4.5 % Sn, 3-5% Pb, 3-9% Zn, 1.5% Fe, 19-21.5% Ni, 1% Mn, and 0.15% Si. Since C97600 is heavily used in the manufacturing of valves fittings and gears for the dairy industry, it has become known as the dairy metal. The alloy was once called ASTM Alloy 11A, but that name is now discouraged.