COMPANY STRUCTURE

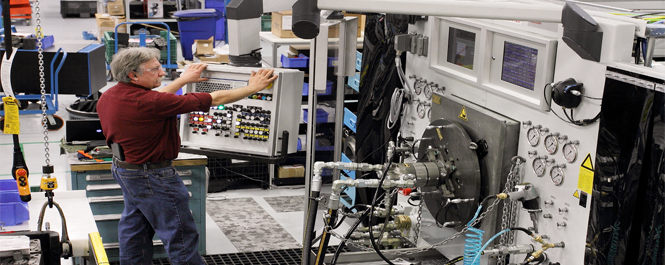

Along with offering years of experience producing centrifugal castings in our on-site foundry in most castable bronze alloys, one of our biggest assets is that we can provide quick service and turn around for your requirements in the event of a breakdown. We have provided this special service, in specific instances, within hours of receiving an order. From supplying semi-finished machined bars to finished bearings and plates machined to close tolerances, in single units or production runs, Hydapac Casting is ready to meet your bronze requirements. Specializing in centrifugal castings our modern foundry and CNC turning/milling equipment gives us the ability to efficiently produce almost any size or shape economically and promptly. Orders are produced to your exact and individual requirements and specifications.

Understanding how metals respond to these conditions helps in selecting the right materials for various industrial applications, from construction to transportation. Let’s look at how metals are tested for corrosion resistance and the different methods used in this process. By evaluating corrosion resistance, engineers and manufacturers can make informed decisions about material selection and design considerations. This helps reduce maintenance costs and prevent potential safety hazards caused by corroded metal components. Over the years, Hydapac has established itself as a leading alloy metals company and steel supplier. We’ve developed considerable credibility with a wide range of end users, both nationally and internationally. From the one-man job shops to the large prime contractors, we make every effort to provide our customers with a quality product, on time, and at a competitive price. We trust you will be pleased with our service and our high standard of quality, which is an essential part of our business plan.