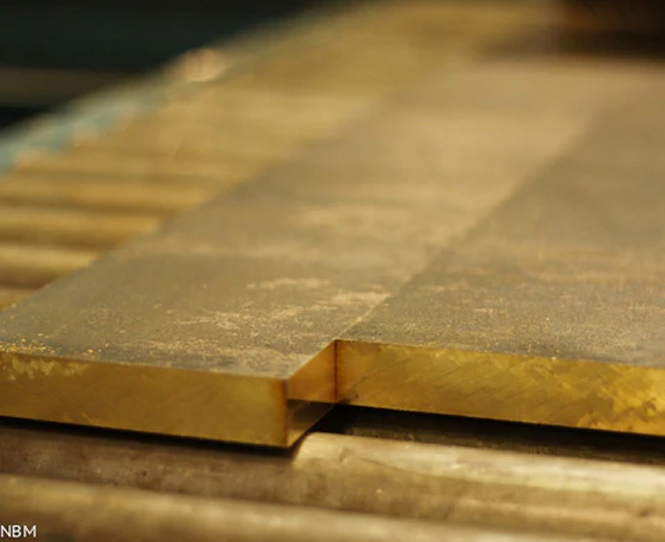

MANGANESE CASTING

Manganese Bronze

Manganese bronze contains small additions of manganese, iron, and aluminum, plus lead for lubricity, anti-seizing, and bonding. Like the aluminum bronzes, they combine high strength with excellent corrosion resistance. Manganese bronze bearings can operate at high speeds under heavy loads, but require high shaft hardness and nonabrasive operating conditions.

The various types of manganese bronze are a popular choice for the aerospace, fastener, marine, and oil and gas Industries. Typical applications in these industries include landing gear parts, strut bushings, screw machine parts, bearings, bushings, gears, and lead screw nuts.

This is a high strength leaded silicon manganese bronze with typically good bearing qualities. This alloy maintains high impact resistance with excellent machinability making it well suited for clutch bearings, shaft bushings, sleeve bearings, thrust bearings, pump parts, drive shafts, bearing pins, wear plates, gears and cams. Resists squashing out under high loads and extreme wear applications.

C67500 represents a wrought alloy of manganese bronze, offering a bronze of moderately elevated strength with commendable tensile properties and overall resistance to corrosion. Furthermore, it exhibits exceptional characteristics for hot working in closed die forging applications.

C67600 manganese bronze stands out as a versatile alloy, extruded and drawn, celebrated for its elevated strength and commendable corrosion resistance. Moreover, C676 demonstrates a relatively low melting temperature and a moderately reduced heat capacity.

C86300 continuous cast manganese bronze is a high strength, non-heat treatable copper alloy intended for use in applications requiring a good combination of outstanding wear characteristics and high bearing strength for heavy loads and slow speeds. Typical applications include slow speed heavy duty load bearings, gears, cams and hydraulic cylinder parts. Conforms to continuous cast specification ASTM B505.