BRONZE CASTING

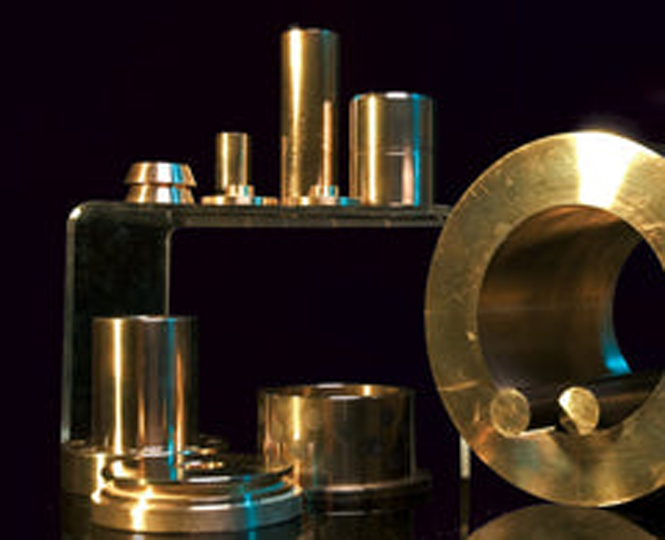

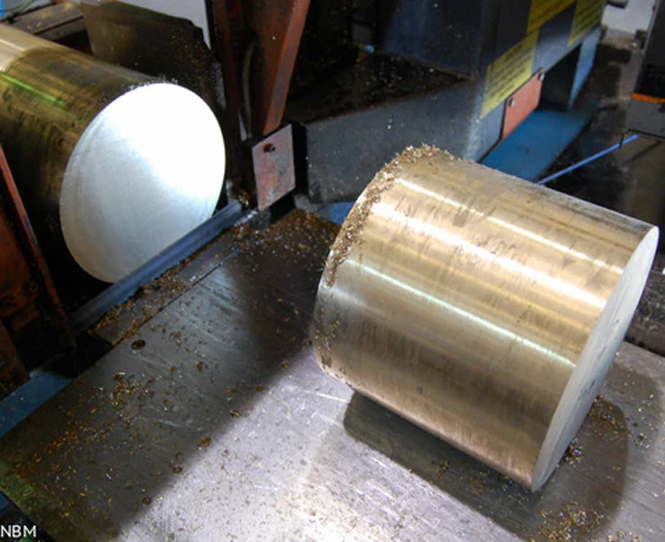

Molten bronze meeting required customer chemical specifications is poured from a furnace into a ladle. The metal is then poured into a spinning mold. The size of the mold determines the outer diameter of the casting. The amount of molten metal poured into the die determines the inner diameter of the casting. The casting is then removed from the die, scheduled for production, machined, and quality tested.

This method of casting ensures a higher quality product, reducing the chance for defective material, and creates a fine grain structure that enhances mechanical properties. Our capabilities for this process can produce machined bronze components with a diameter of 100″ or larger. Centrifugal castings are produced in accordance with ASTM B271, ASTM B427, ASTM B22, or to an applicable customer specification.

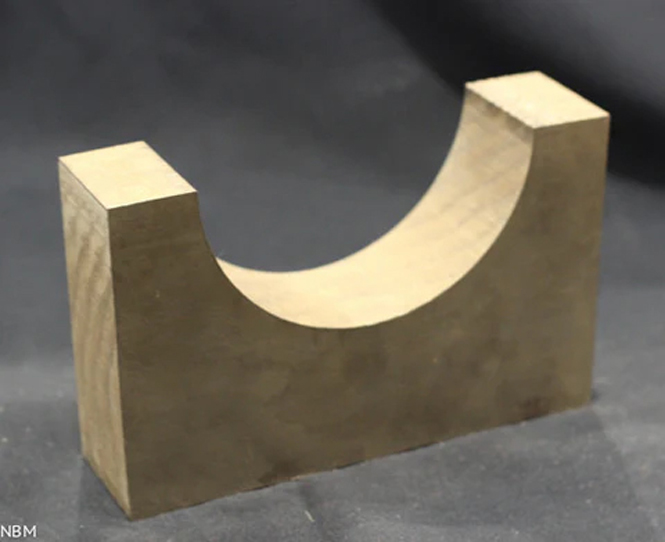

Some examples of quality bronze components that are produced using this casting method are: Plain Bronze Bushing, Full-Split Bronze Bushing, Flanged Bronze Bushings, Self-Lubricated Bronze Bushings (Impregnated Graphite), Gear Blaks, Bronze Sleeve Bushings, Thrust Washers, Split Half Bronze Bushings (Saw-Split Bronze Bushings), Adjusting Nuts, Bronze Bearings, Impeller Wear Rings, Labyrinth Rings, Pump Shaft Sleeve, Impeller Shaft Sleeve, Casting Rings

Leaded Manganese Bronze C86400 (Bronze CDA 86400), also known as Leaded High Strength Yellow Brass, is a cast Copper alloy that is made of Copper and Zinc, with Aluminum, Lead, Tin, Iron, Manganese and Nickel & Cobalt. This cast bronze is primarily used in roller bearing applications.

High Strength Yellow Brass C86400 (CuZn40Fe2AlMnPb) is an alpha-beta brass with additions of 2% Fe and 1% additions of aluminium, lead and manganese. The iron, aluminum, and manganese, provides additional strength and corrosion resistance, while the lead is added to increase the machinability.

The alloy has good wear resistance and is used for roller bearing cages where the properties of high strength, ductility, good fatigue, excellent bearing, and excellent machinability make it a popular choice.

The Bronze CDA 86400, offered by Wieland Diversified, is a testament to their commitment to manufacturing products of the highest quality. This alpha-beta brass alloy exhibits remarkable properties that make it a top choice among industries that need robust and reliable bronze components.

Moreover, those of us at Wieland Diversified are known for our high transparency and integrity. We provide comprehensive product documentation, ensuring you are fully informed about the material’s properties and potential applications. This commitment to customer education allows you to make well-informed decisions, maximizing your investment’s value. In addition, Wieland Diversified offers competitive pricing for Bronze CDA 86400, ensuring that you receive plenty of value for your money. This commitment to affordability, coupled with their exceptional product quality, makes Wieland Diversified an excellent choice for your bronze alloy needs.

We specialize in brass and bronze sand castings used in a variety of industrial applications around the world. As a bronze casting company, we are experts in helping you choose the proper alloy for your casting. Types of bronze alloys we manufacture include: Aluminum Bronze, Manganese Bronze, Tin Bronze, and Silicon Bronze. The markets we serve are a testament to the quality bronze castings we provide. In addition to bronze sand castings, we are also a manufacturer of Aluminum Tubes & Rings rough machined, and used as bearings, labyrinth seals, and bearing housings. Our proprietary process – an improvement on centrifugal casting – in three hard to find Aluminum Alloys puts us above the rest. These aluminum alloys include AL850, AL852, and AL443. While we do not pour AL6061, the previously listed alloys can provide superior machinability and lubricity to AL6061. Our foundry can support both low volume and high volume production runs.

Our low volume production capabilities allow our customers to order castings and other products with a short run strategy. With our technology, we are able to take on short production runs with accuracy and efficiency offering a turnaround time of 3 to 9 weeks depending on factors like complexity and applied auxiliary services. With our automated molding line, Erie Bronze can offer high volume production runs with consistency and accuracy all delivered in a timely manner. Lead times on production run items typically range from 1 to 6 weeks, and our high volume bronze sand castings can range from 3 to 150 pounds.

STAINLESS STEEL CASTING

Stainless Steel Alloy Products

At Wieland Diversified, we have a large selection of stainless steel metal products to satisfy your unique application.

Stainless steel metal is an alloy family that encompasses several diverse compositions. This iron-based alloy is supplemented with various alloy materials, such as nickel, carbon, silicon, titanium, copper, and many more. Some of our most popular options include 17-4 stainless steel and 304 stainless steel.

This alloy is a top choice because it possesses several desirable properties. In addition to its low maintenance benefits, it’s also corrosion- and stain-resistant. Its shiny, sleek appearance is another common selling point. Many industries use our stainless steel alloy products to create necessary parts, structures, and frames. A few industries that use stainless steel include the aerospace, automotive, and architecture industries.

Alloy A286 features high strength, oxidation resistance, and corrosion resistance at continuously high temperatures. A286 alloys are heat treatable to achieve a wide variety of grain structures and tensile properties. This grade of A286 is annealed and aged. Applications for Alloy A286 include jet engine components, superchargers, turbine wheels and blades, fasteners, springs, and general high-stress components in petrochemical, aerospace, and oil patch industries.

A286 is an iron-nickel-chromium alloy with additions of molybdenum and titanium. A286 is one of the most popular high-temperature alloys. As one of the austenitic alloys, it maintains good strength and oxidation resistance at temperatures up to 1300ºF (700ºC).

It also contains niobium for stabilization against sensitization and resultant intergranular corrosion. A286 has excellent resistance to general corrosion, pitting, and crevice corrosion in chemicals containing chlorides and sulphuric, phosphoric, and nitric acids. Used for tanks, piping, heat exchangers, pumps, valves, and other process equipment.

15-5 Stainless Steel is a martensitic, precipitation hardening, Chromium-Nickel-Copper Stainless Steel. The Stainless 15-5 alloy combines high strength, transverse toughness and ductility, hardness capability and corrosion resistance compared with 304 stainless.

The general level of corrosion resistance is best in the fully hardened condition and decreases slightly as the aging temperature is increased. 15-5 Stainless may also be used in the solution treated condition or heat-treated to obtain a wide variety of properties.

This alloy is used in aerospace, aircraft components, fabricated parts in high- pressure corrosive environments including valves, shafts, fasteners, fittings, and gears.

Stainless Steel 17-4 H1025 is a precipitation-hardening martensitic Stainless Steel, which has corrosion resistance comparable to austenitic varieties. Our H1025 has been heat-treated to the minimum tensile strength of 155ksi, yield strength of 145ksi, an elongation in 2in of 12%, and a reduction of area of 45%. Cobalt is reported in the chemistry.

Save time and money by buying the material for your heat treatment. We do all work in large batches, driving the cost down, and offering you fast delivery. Free heat treat charts will be included in our cert package upon request.

Stainless Steel 17-4 H1075 is a precipitation-hardening martensitic Stainless Steel, which has corrosion resistance comparable to austenitic varieties. Our H1075 has been heat-treated to a minimum tensile strength of 145ksi, yield strength of 125ksi, an elongation in 2in of 13%, and a reduction of area of 45%. Cobalt is reported in the chemistry.

Save time and money by buying the material to your heat treatment. We do all work in large batches, driving the cost down and offering you a fast delivery. Free heat treat charts will be included in our cert package upon request.

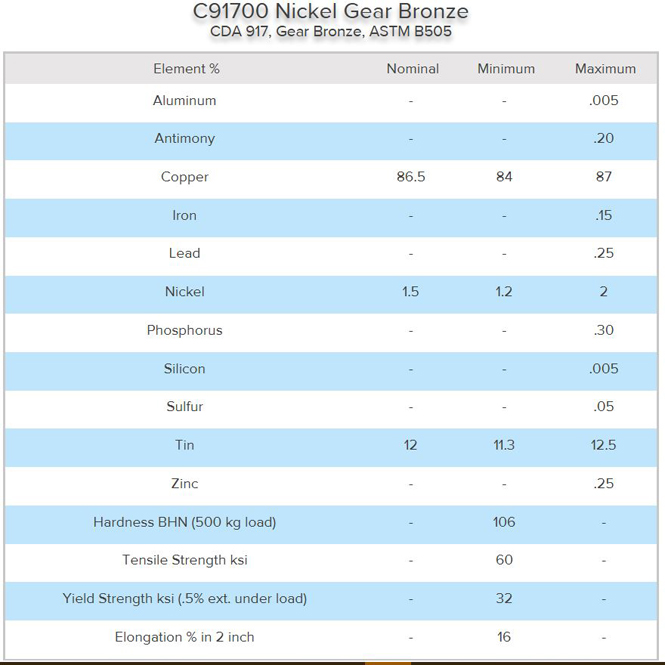

NICKEL TIN BRONZE CASTING

Nickel Tin Bronze

We offer Nickel tin bronze, including leaded, nickel gear, and “spinodal” bronzes. Common applications include worm wheels, worm gears, cams, pump bodies, and more. Take a look at all of our nickel tin bronze products here!

Typical Uses for C91700 Nickel Tin Bronze (Nickel Gear Bronze):

INDUSTRIAL: Worm Wheels, Worm Gears, Conprise Gears, Heavy Load, Relatively Low Speed Bearings

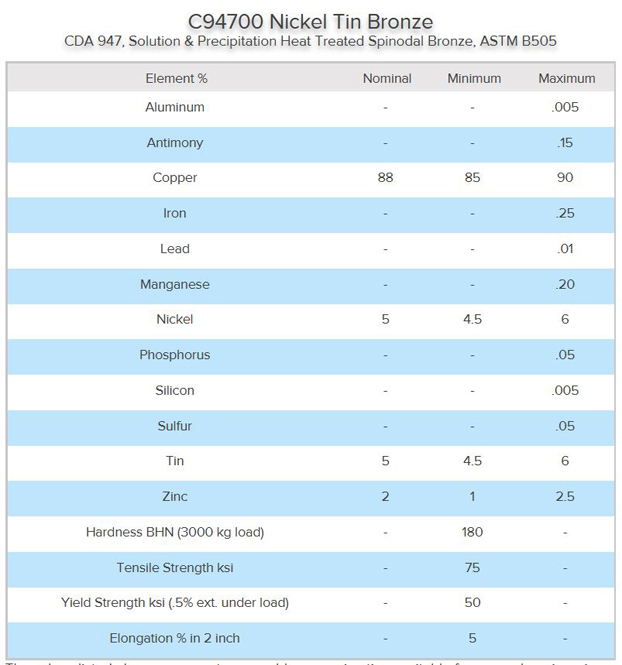

C94700 Nickel Tin Bronze "Spinodal"

Typical Uses for C94700 Nickel Tin Bronze "Spinodal":

INDUSTRIAL: Feeding Mechanisms, Gears, Shift Forks, Piston Cylinders, Wear Guides, Valve Components, Bearings, Nozzles

C96900 Nickel Tin Bronze (Spinodal Bearing & Bushing Bronze Systems)

This is a high-performance alloy which can withstand high loads and operate under severe conditions. An excellent low friction, non-corrosive bronze alloy now available from our inventory.

Nickel alloys contain several beneficial properties, such as heat and corrosion resistance, which make them ideal for high-temperature environments. A wide range of alloy combinations offer versatility—nuclear power and electrical industries often use these metals in steam and aircraft turbine manufacturing, but they also have many practical uses across other industries.

We have an abundant selection of nickel alloys at Wieland Diversified. From Nickel 400 to Hastelloy X, our diverse product line is designed for your custom requirements. Each alloy contains a different nickel concentration, which affects the composition’s properties. This adaptability allows you to use these alloys in various environments and temperature conditions.

NICKEL ALUMINUM BRONZE CASTING

Nickel Aluminum Bronze Alloys

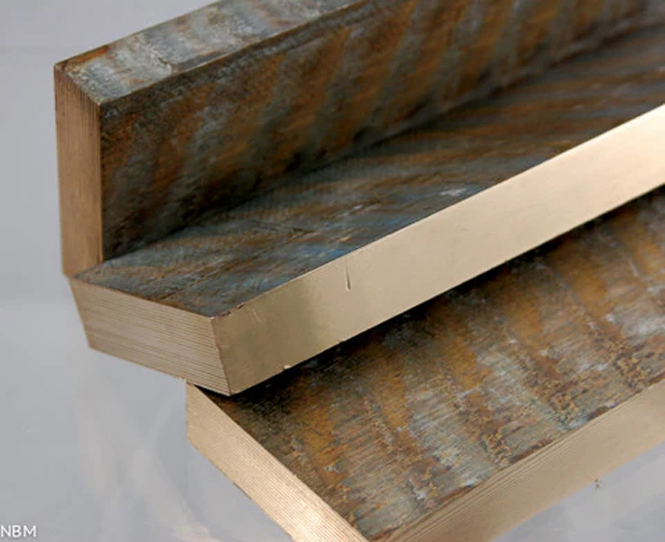

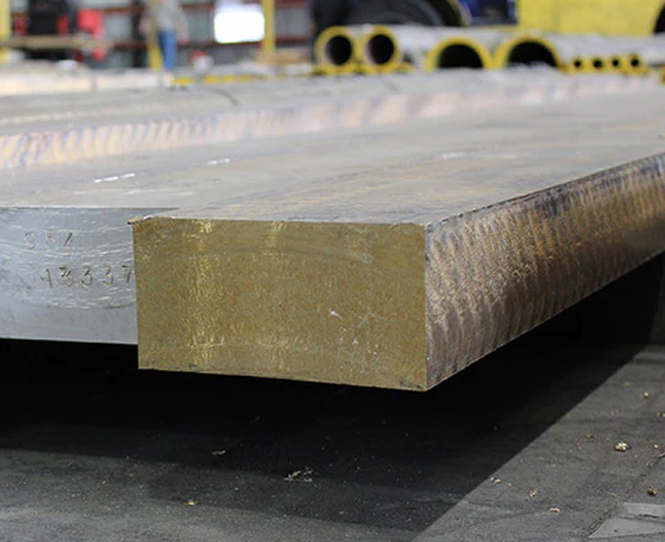

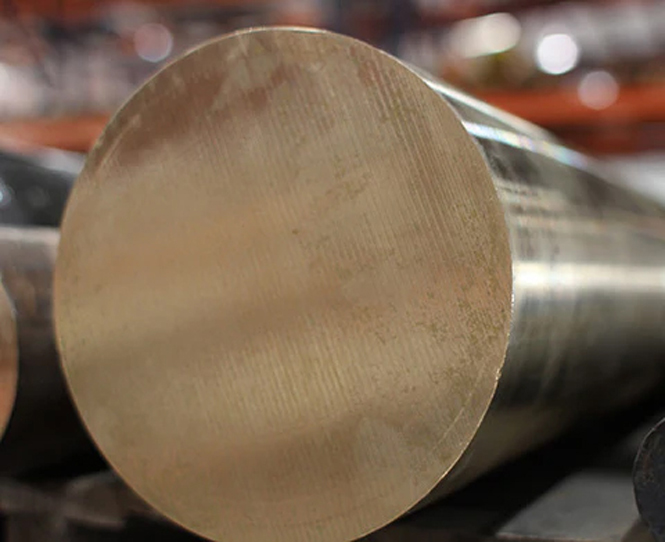

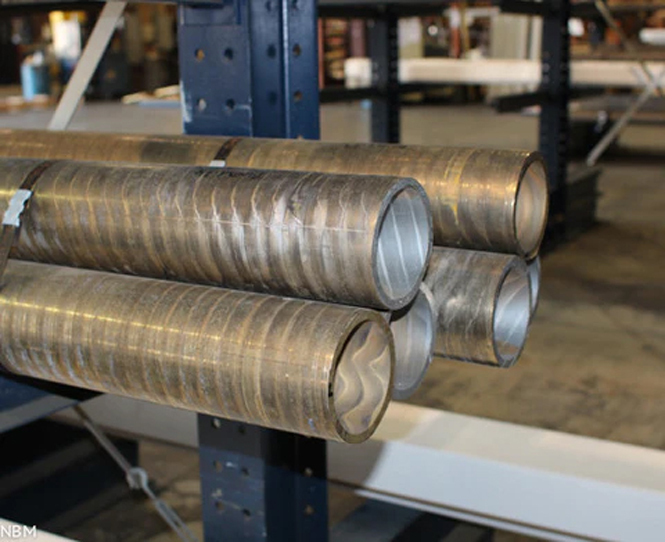

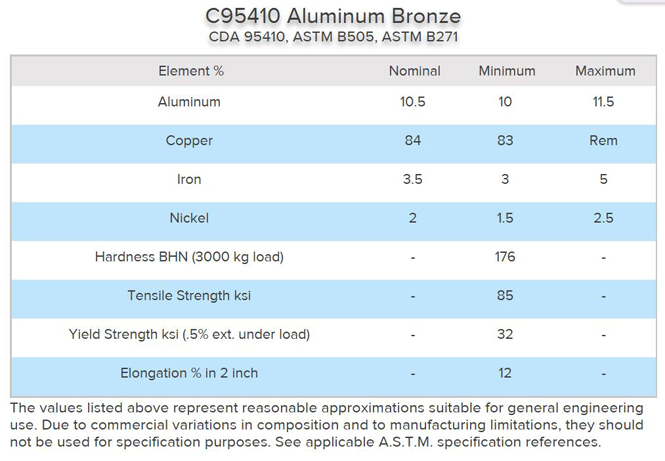

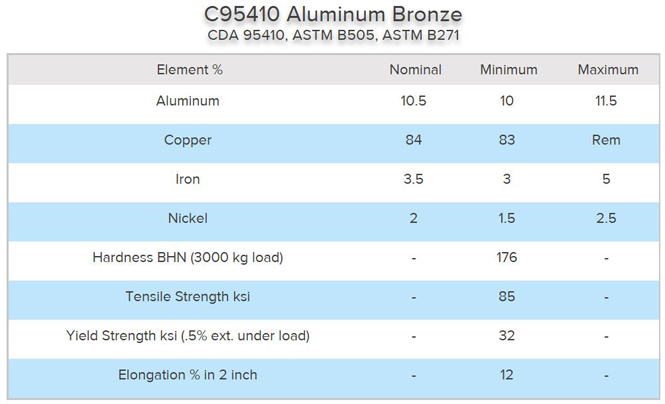

Nickel aluminum bronze alloys contain 5 to 11 percent aluminum, as well as additions of iron and nickel for strength. Increasing the aluminum content of bronze results in higher strength. These nickel aluminum bronze alloys are used for bushings, bearings, wear plates, and hydraulic valve components. Nickel aluminum bronze is available in rod, tube, and plate forms.

Applications for Nickel Aluminum Bronze

The various types of nickel aluminum bronze alloys are a popular choice for industrial applications such as landing gear bushings and bearings for the aerospace industry, propeller hubs, wear rings, and hardware for the marine industry, a piping for vertical pump columns, firefighting and fire suppression systems, and seawater lift pumps for the oil and gas industry, hydraulic bushings for earth moving equipment, as well as many other applications. This is due specifically to the addition of nickel which improves the corrosion resistance of the already versatile aluminum bronze alloys. Iron acts as a grain refiner and increases tensile strength without diminishing its excellent ductility and toughness.

Nickel Aluminum Bronze offers high ductility, high electrical and thermal conductivity, high impact strength, good creep resistance, ease of welding, and low volatility under high vacuum.

INDUSTRIAL: Bearings, Bushings, Valve Balls, Forming Dies for Roll Bearings, Hydraulic Bushings for Earth Moving Equipment, Valve Parts - Cryogenic

AMS 4640 Nickel Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance.

INDUSTRIAL: Hydraulic Bushings for Earth Moving Equipment, Corrosion Resistant Articles, Heat Exchanger Flanges, Heat Exchanger Headers, Tanks, Valve Balls, Structural Members, Pump Shafts, Valve Guides, Plunger Tips, Welded Piping Systems, Balls, Gears, Cams, Pump Parts, Shafting, Condenser Tube for Power Stations and Desalting Units, Valve Seats

AMS 4880 Nickel Aluminum Bronze is one of the most popular landing gear bushing materials specified today along with AMS 4640 material. NBM's brand of AMS 4880 is continuous cast and heat treated. Our AMS 4880 has outstanding mechanical properties and typically exceeds those of AMS 4640. In many cases NBM's AMS 4880 can be substituted for AMS 4640 with the advantage of our material being available in hollow bar, which provides for great cost savings due to weight reductions and a huge elimination of scrap. We can also supply rough machined blanks in this alloy, which helps to reduce scrap issues even further. Please send us your drawings.

Typical Uses for AMS 4880 Nickel Aluminum Bronze:

AEROSPACE: Landing Gear Bushings & Bearings, Valve Guides, Stems, Seats

INDUSTRIAL: Corrosion Resistant Parts, Wear Rings, Machine Tool Parts, Piston Guides, Worm Wheels, Hot Mill Gurdes

MARINE: Propeller Hubs, Wear Rings, Hardware, Worm Gears, Shafts, Sleeves

A special heat treatment process improves mechanical properties and strength-weight ratio beyond the range of commercial aluminum bronzes. For applications involving heavy loads, abrasive wear, friction, deformation and high temperatures.

C63000 (AMS 4640 - CDA 630) Aluminum Bronze alloy is an excellent choice for applications involving heavy loads, abrasive wear resistant, friction, abrasive wear and corrosion. The addition of nickel increases the alloys strength without diminishing its excellent ductility, toughness and corrosion resistance. Typical applications for C63000 nickel aluminum bronze included aircraft landing gear components, strut bearings, main pistons, trunnion bearings and similar vital components.

AMS 4881 is offered in solid and hollow bars. The additional heat treating process improves mechanical properties and the strength to weight ratio exceeding the range of typical aluminum bronzes.

AMS 4881 is commonly used in applications involving heavy loads abrasion, friction, and deformation at high temperatures. In many cases AMS 4881 can replace AMS 4590/C63020 with the advantage of this material being available in tube form, which provides economic cost savings to you the customer.

MANGANESE CASTING

Manganese Bronze

Manganese bronze contains small additions of manganese, iron, and aluminum, plus lead for lubricity, anti-seizing, and bonding. Like the aluminum bronzes, they combine high strength with excellent corrosion resistance. Manganese bronze bearings can operate at high speeds under heavy loads, but require high shaft hardness and nonabrasive operating conditions.

The various types of manganese bronze are a popular choice for the aerospace, fastener, marine, and oil and gas Industries. Typical applications in these industries include landing gear parts, strut bushings, screw machine parts, bearings, bushings, gears, and lead screw nuts.

This is a high strength leaded silicon manganese bronze with typically good bearing qualities. This alloy maintains high impact resistance with excellent machinability making it well suited for clutch bearings, shaft bushings, sleeve bearings, thrust bearings, pump parts, drive shafts, bearing pins, wear plates, gears and cams. Resists squashing out under high loads and extreme wear applications.

C67500 represents a wrought alloy of manganese bronze, offering a bronze of moderately elevated strength with commendable tensile properties and overall resistance to corrosion. Furthermore, it exhibits exceptional characteristics for hot working in closed die forging applications.

C67600 manganese bronze stands out as a versatile alloy, extruded and drawn, celebrated for its elevated strength and commendable corrosion resistance. Moreover, C676 demonstrates a relatively low melting temperature and a moderately reduced heat capacity.

C86300 continuous cast manganese bronze is a high strength, non-heat treatable copper alloy intended for use in applications requiring a good combination of outstanding wear characteristics and high bearing strength for heavy loads and slow speeds. Typical applications include slow speed heavy duty load bearings, gears, cams and hydraulic cylinder parts. Conforms to continuous cast specification ASTM B505.

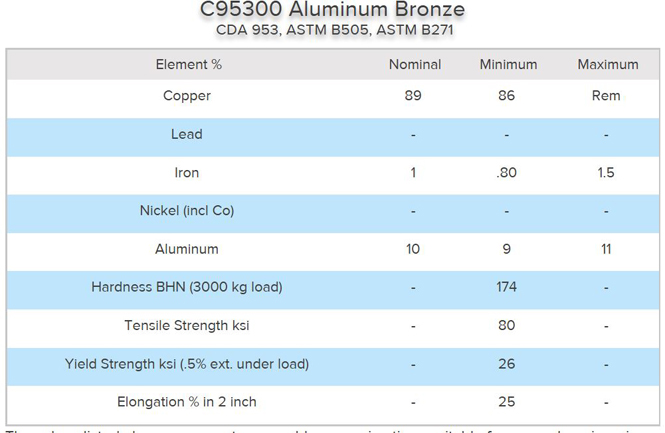

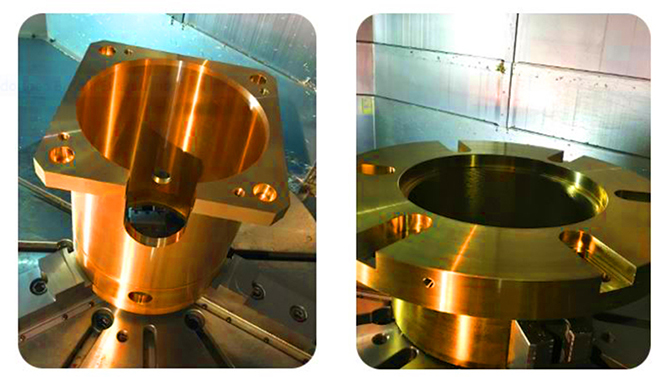

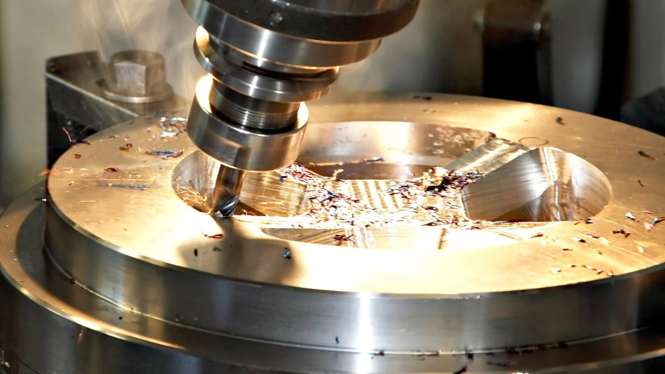

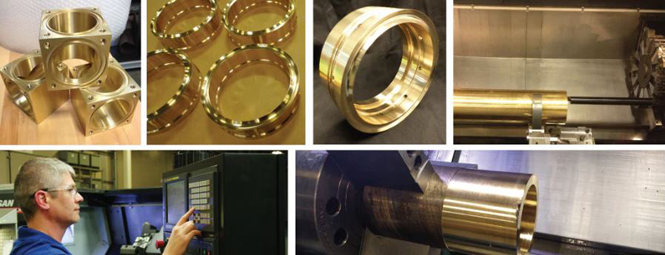

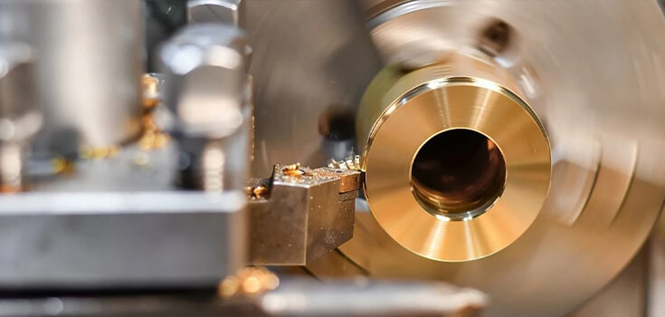

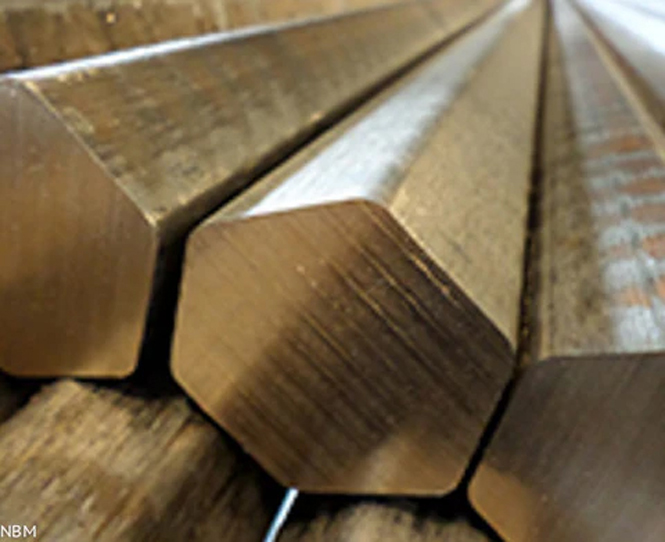

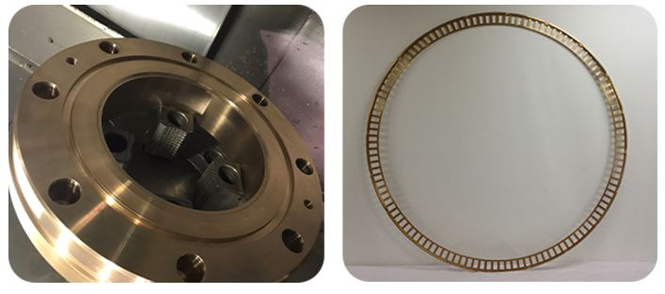

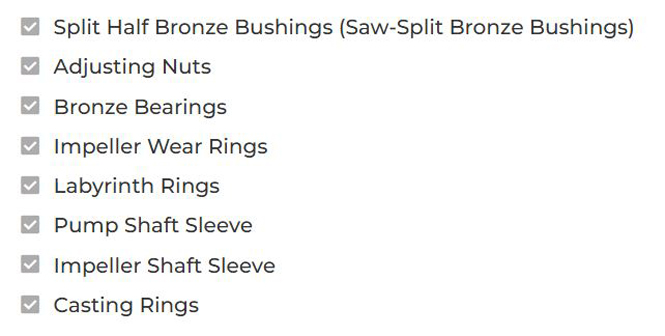

MACHINING

We are now also offering our complete range of brass, bronze and copper alloys in precision machined or milled parts, in full accordance with your drawings.

We creates custom precision bearings and bushings, flanges, washers, double flange bearings, full half bearings, spacers and special machined parts that can be shipped on a global basis and in full accordance with most international standards.

We produce machined parts for the following industries;

oil and gas, aerospace, mining and construction, agricultural, transportation and railways, telecom, automotive, medical, and fluid controls.

We fully committed in on-going investments for our manufacturing facilities, production equipment, testing equipment, including various CNC's. We also have outstanding management and operators of the highest order working together as a unified team, producing excellent quality machined parts.

Services and Specialties

We can machine all brass, bronze and copper alloys to meet your most demanding requirements.

Precision CNC Turning, Boring and Milling

Prototype to Full Production Runs

Turning Capabilities : 1" — 24" Diameters

Milling Capabilities : 22" x 48"

Typical Tolerances that we can hold: +/- 0.0005"

From Casting to Finished Machined Product & Blanks

Our Quality Assurance Department has the equipment and processes to guarantee the quality of the products we manufacture.

Each order undergoes stringent quality assurance processes to assure accuracy and precision to the client's specifications.

This process begins with our highly trained and experience Quality Engineering Department who utilize our core tools (APQP, PPAP, FMEA, MSA, SPC), continues through in-process inspections, and ends with a final inspection.

We are always seeking to newly improve and upgrade our machining capabilities with the latest technology. With over 20 computer numerical controlled machines (CNC) and over 20 manual machines including turret lathes, vertical mills, horizontal mills our capabilities are endless.

These capabilities allow us to supply parts to our customers from 1″- 100″ in diameter and lengths up to 60″.

Bushings, washers, spacers, seal rings, wear plates, liners, and gibs are economically cast from a fraction of an inch to several inches thick and are machined to specific shapes and sizes holding tolerances as close as .001″ of an inch.

We look forward to receiving your valued inquires, and working with you to contribute to the continued success of your business.

LEADED RED BRASS CASTING

Red Brass Alloy

Red brass is the most durable of all metals for the plumbing industry and commercial water pipe applications. It is excellent for resistance to dezincification and season cracking which most high copper brasses are known for. Dezincification Resistant Alloys (also known as DZR or DR Alloys) such as Red Brass C352 has a small amount of arsenic added to the alloy in order to prevent chlorinated water from leaching the zinc from your plumbing products which eventually leads to the weakening and cracking of your plumbing products.

Red brass is also specified for underground service lines since it offers great corrosion resistance to all types of potable waters, and has moderate strength and good retention of spring properties.

Red Brass Applications Formed into fittings & nipples for carrying water in commercial plumbing and OEM applications. Low cost bearing materials.

Naval Brass C46400 is nominally composed of 60% copper, 39.2% zinc, and 0.8% tin. As is typical of brass alloys with the duplex alpha + beta structure, C46400 has good strength and rigidity. By substituting tin for an equal quantity of zinc, a high corrosion resistance to seawater is achieved. The addition of tin also gives the alloy an inherent resistance to dezincification, thereby further inhibiting the impingement by seawater at higher than normal temperatures. The alloy is also noted for its resistance to wear, fatigue, galling, and stress corrosion cracking.

C693 Lead-Free Brass has excellent dezincification corrosion resistance and excellent stress corrosion cracking resistance. One if its unique features is that it is corrosion resistant to chemicals found in water and gas. It has high strength equivalent to stainless steel. It also has good machinability, excellent hot forgeability, easily accepts solder and brazing, and has excellent polishing and plating capabilities. C69300 Lead-Free Brass is compliant with the Federal Drinking Water Act, and it also support applications following the U.S. EPA standards for antimicrobial performance.

C23000 brass is the most durable of all metals for commercial water pipe in the practical price range. Excellent for its resistance to dezincification and season cracking for which the high copper brasses are known. Moderate strength and good retention of spring properties. Specified for underground service lines since it offers greatest corrosion resistance to all types of potable waters. Applications for C23000 brass include costume jewelry, fire hose couplings, zippers, condenser and heat exchanger tubes. Popular as an outdoor metal and has found for itself a very important place in modern architecture. Also known as Nordic Brass. The EN equivalent for this alloy isåÊCuZn15.

C83600 Leaded Red Brass, also known as 85 metal, is the most common red brass containing 85% copper and 5% each of tin, lead and zinc. Typical uses for red brass involve electrical hardware, fixtures, pumps and more. Aviva Metals offers C83600 Leaded Red Brass, SAE 40 in a variety of shapes including bars, pipes and tubes. INDUSTRIAL: Handles for Dental Equipment, Air Actuators, Valve Bodies, Valves, Bushings, Pump Parts, Pumps, Valve Bodies, Impellers, Pump Fixtures, Couplings, Valves, Transducer Housings, Valve Bodies for the Water Meter Industry, Valves for the Water Meter Industry, Pumps, Low Pressure Valves, Small Gears, Bearings, Bearing Segments for Steel Industry, Pressure Blocks for Steel Industry, Rings, Printing Presses, Furnace

C84400 is the most widely used alloy in the semi-leaded red brass family, known for its reasonable cost with good machining and casting properties. The lead content ensures pressure tightness. Red brass is also used for low-cost bearing materials under low loads. This group of alloys is typically found in plumbing applications. See more applications below.

COPPER NICKEL CASTING

Copper Nickel Alloy

Copper nickel alloys, also known as Cu-Ni, offers excellent corrosion resistance, especially in marine salt water environments. Copper nickel alloys that are generally chosen for sea water parts and service equipment contains 10 to 30 percent nickel.

We stocks C70600 and C71500 Copper Nickel pipes, which are commonly used in seawater piping due to its complete resistance to barnacles. Due to Its resistance of various sea organisms, this alloy makes seawater desalination, water systems, fire fighting systems, and similar applications very reliable.

These various alloys also have important additions of iron and manganese, which are necessary to maintain good corrosion resistance in the harsh environments. Aside from being very corrosion resistant to sea water, copper nickel alloys are very thermally stable. Copper nickel is most commonly used in applications such as electrical and electronic products, tubes for condensers in ships and power plants, various marine products, including valves, pumps, fittings, and sheathing for ship hulls.

APPLICATIONS Marine hardware Desalination Seawater piping systems Cooling loops Pipe nipples Copper Nickel Alloy Product Selection

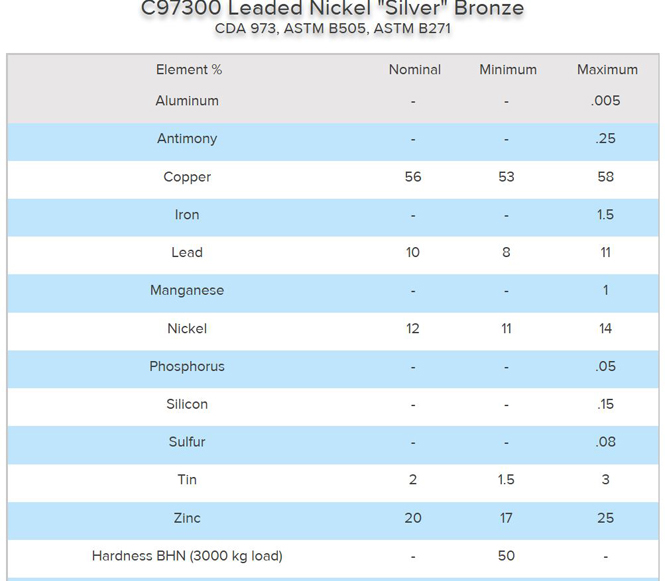

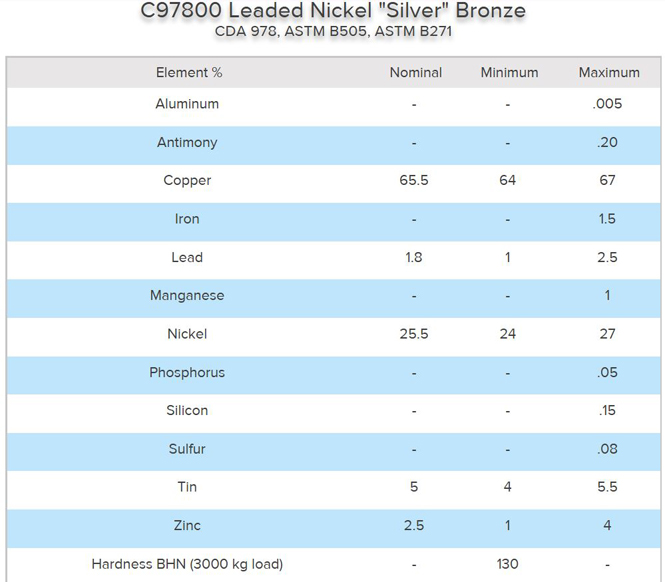

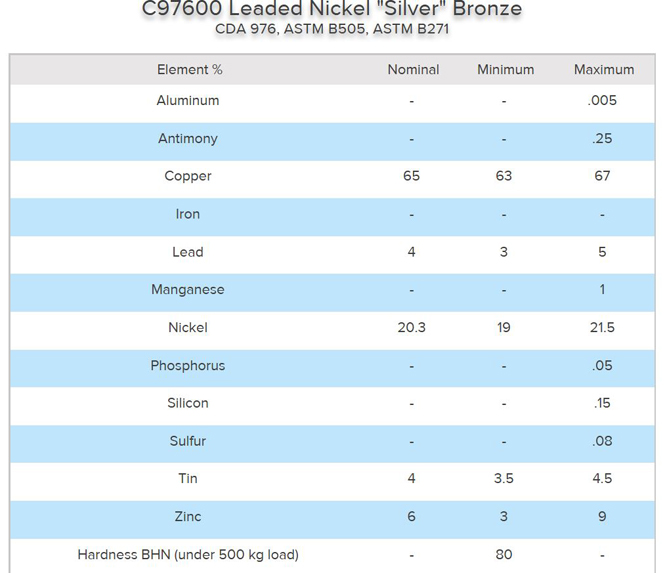

Nickel silver bronze are alloys that contain copper, tin, lead, nickel, and zinc. Nickel silver bronze has low to moderate strength and good corrosion resistance and are named for their silvery luster.

They are used in the food and beverage handling equipment, decorative hardware, electroplated table ware, optical and photographic equipment and musical instruments.

We offer Nickel tin bronze, including leaded, nickel gear, and “spinodal” bronzes. Common applications include worm wheels, worm gears, cams, pump bodies, and more. Take a look at all of our nickel tin bronze products here!

C70600 (C706) & C71500 (C715), Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some of the primary uses for C706 include copper nickel fittings (CuNi Fittings) as well as condensers and exchanger shells.

C70600 & C71500, Copper nickel offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel. They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, and pump components.

Offers excellent corrosion resistance, especially in marine salt water environments. The main, wrought copper-nickel alloys chosen for sea water service contain 10 or 30 percent nickel.

They also have important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

CuNi10Fe1Mn, Copper nickel also has important additions of iron and manganese which are necessary to maintain good corrosion resistance. Some common applications for copper nickel include: valves, pump components, fittings, flanges and various other marine hardware components.

C97600 Nickel Silver Bronze, also referred to as dairy metal or dairy bronze, is a cast bronze alloy with a high machinability rating of 70. C976 Dairy Bronze contains 63-67% Cu, 3.5-4.5 % Sn, 3-5% Pb, 3-9% Zn, 1.5% Fe, 19-21.5% Ni, 1% Mn, and 0.15% Si. Since C97600 is heavily used in the manufacturing of valves fittings and gears for the dairy industry, it has become known as the dairy metal. The alloy was once called ASTM Alloy 11A, but that name is now discouraged.

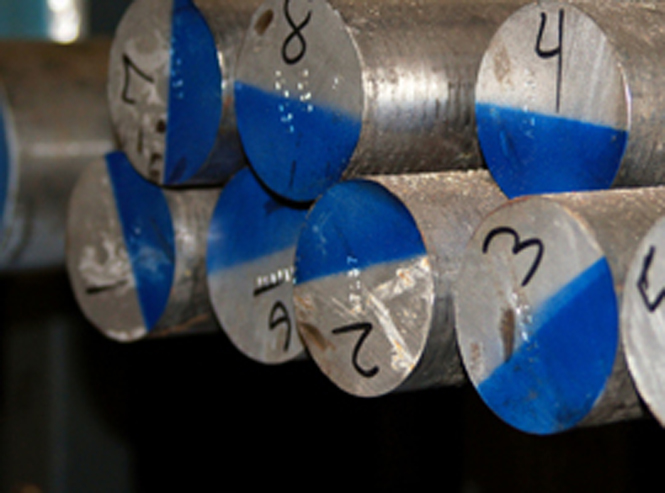

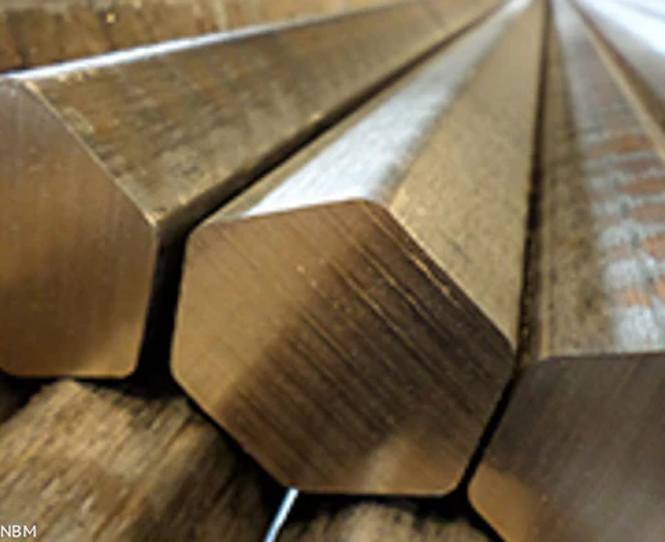

CONTINUOUS CASTING

Continuous Cast Alloys

Benefits of continuous casting include the following:

Excellent machinability and fabrication ability Uniform structures Favorable mechanical properties Greater friction and wear properties Reasonable cost

NBM C90300 Lead Free Tin Bronze, also known as modified Navy G, is a high wear resistant that provides good mechanical properties and excellent corrosion resistance to dezincification.

This proven alloy is used in wide applications and has a excellent rating for soldering and offers good brazing.

Common applications include lead free applications, plumbing fixtures, potable water applications, bearings & bushings, seal rings, gears, piston rings, pump impellers, steam fittings, valve components, marine fittings and pump components and many more.

Castings for bearings, bushings and gears available in continuous cast bar, tube and plate. CDA 907 bronze solid round bars available from stock.

C93200 Bearing Bronze / High Leaded Tin Bronze has excellent machining properties, good hardness, strength and wear resistance with excellent anti-friction qualities. The alloy is not subject to dezincification and has reasonable corrosion resistance to seawater and brine making it suitable for pump and valve components.

C93200 bronze is suitable for bearings, bushings having medium loads and speeds with adequate lubrication.

INDUSTRIAL: Railroad Engine Casings, General Service Bearings for Moderate Pressure, Wearing Material for Rod Bushings, Wearing Material for Wedges, Wearing Material for Shoes, Pump Impellers for Acid Mine Water, Pump Bodies for Acid Mine Water,

Freight Car Bearings, Backs for Lined Journal Bearings for Locomotives, Backs for Lined Journal Bearings for Passenger Cars, Bearings, Pumps, Industrial Centrifuges, Machine Parts, Low Friction, Moderate Pressure Bushings, Railroad Applications, Acid Resisting Applications

C93700 has excellent machining properties at 80%, medium strength and good corrosion resistance and will withstand mild acids as found in mine water. Bearings manufactured from C93700 have excellent wear resistance under conditions of high speed, heavy pressure and vibration, have low friction and can be used where lubrication is less than adequate and there may be minor misalignment.

C93700 bearings require a hardened shaft and maximum shaft surface speeds of 4 m/sec can be tolerated.̴Ì_

C936 High Leaded Tin Bronze has the following applications: Industrial: Bushings for corrosion, lubrication or pressure, Cam Bushings for Diesel Engines, Crankshaft Main Bearings, Guide Bushings for Piston Rods, Guide Bushings for Valves, Hydraulic Gland Seals, Locomotive Bearing Parts, Main Bearings for Presses, Piston Pin Bearings,

Pump Sleeves, Rod Bushings, Rolling Mill Bearings, Sleeve Bushings (for Cranes, etc.), Bearings for corrosion, lubrication or pressure.

C941 also known as CDA 941 High-leaded tin bronze alloys typically contain between 7 percent and 30 percent lead. This category of alloys is known for its excellent machinability, along with advantageous thermal conductivity and lubrication properties conferred by the lead content. High-leaded tin bronzes find particular utility in bearing applications where lubrication may be compromised.

They excel in harsh conditions where contaminants like dirt pose a threat, as their pliable nature allows them to encapsulate foreign particles, thereby safeguarding the integrity of mating surfaces.

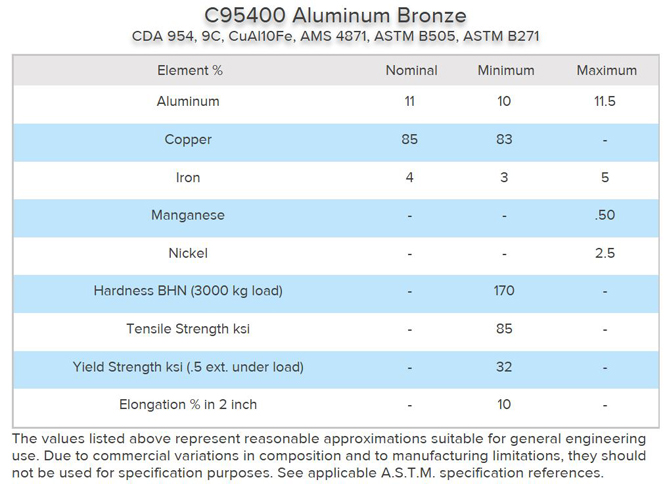

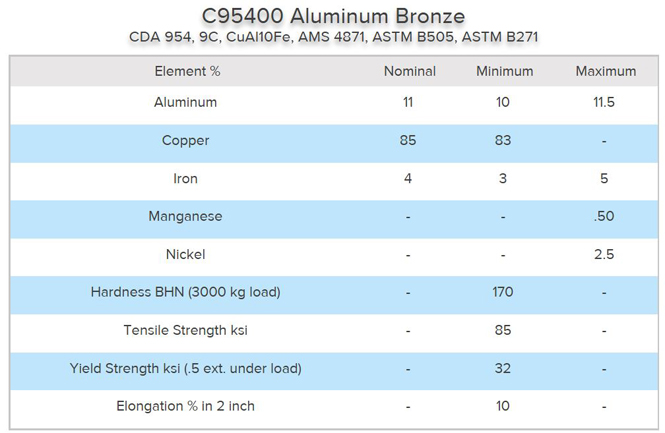

C95400 Aluminum Bronze, also known by C954, is the most popular, all purpose aluminum bronze alloy. It provides high yield and tensile strength, good ductility, weldability and exceptional resistance to wear, fatigue and deformation under shock or overload.

Typical applications include bearings, gears, valve components, wearplate and wearstrip. Conforms to continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

C95500 aluminum bronze offers superior salt water corrosion resistance. It also is resistant to cavitation and erosion. Along with the advantage of pressure tightness, this high strength alloy is excellent for welding and is available in many forms at a lower cost to you.

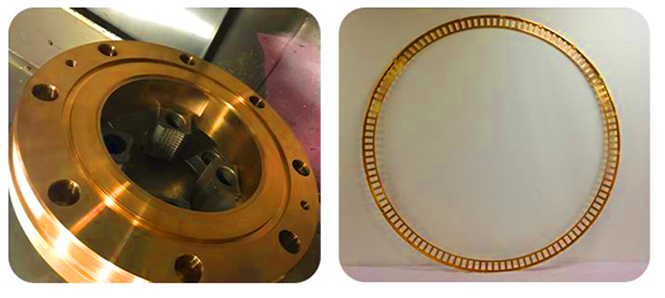

CENTRIFUGAL CASTING

This process allows us to provide a wide range of alloys to our customers.

Centrifugal Casting Process: Molten bronze meeting required customer chemical specifications is poured from a furnace into a ladle. The metal is then poured into a spinning mold. The size of the mold determines the outer diameter of the casting. The amount of molten metal poured into the die determines the inner diameter of the casting. The casting is then removed from the die, scheduled for production, machined, and quality tested. This method of casting ensures a higher quality product, reducing the chance for defective material, and creates a fine grain structure that enhances mechanical properties.

Our capabilities for this process can produce machined bronze components with a diameter of 100″ or larger.

Centrifugal castings are produced in accordance with ASTM B271, ASTM B427, ASTM B22, or to an applicable customer specification.

Some examples of quality bronze components that are produced using this casting method are:

Plain Bronze Bushing Full-Split Bronze Bushing Flanged Bronze Bushings Self-Lubricated Bronze Bushings (Impregnated Graphite) Gear Blaks Bronze Sleeve Bushings Thrust Washers Split Half Bronze Bushings (Saw-Split Bronze Bushings) Adjusting Nuts Bronze Bearings Impeller Wear Rings Labyrinth Rings Pump Shaft Sleeve Impeller Shaft Sleeve Casting Rings

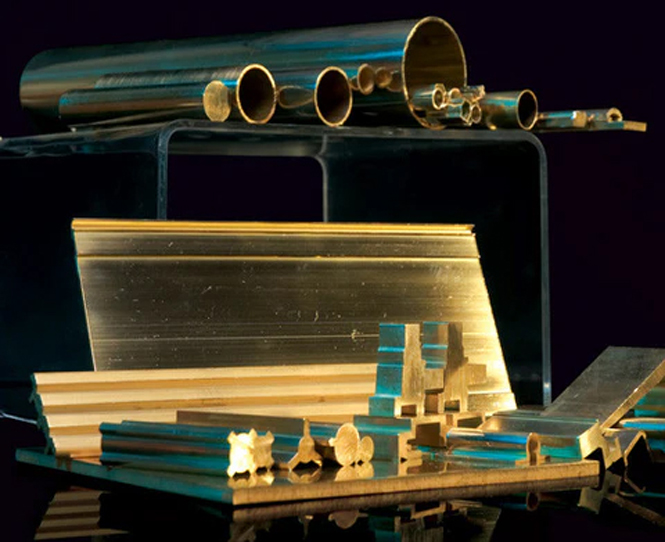

BRASS CASTING

Brass is a popular material in many industries. Its gold-like appearance, its remarkable properties, and its use for artistic purposes have made it a favorite. How can one achieve high-quality and precise results when casting brass? Brass casting is an intricate process that involves melting brass alloy, pouring it into a mold, and creating the desired shape. Precision, attention to detail, and an understanding of material properties are required.

This journey is worth taking, and you’ll gain valuable insight into brass casting by the time you finish this article. You’ll be able to take your project to the next step.

Brass casting is an innovative manufacturing process that involves melting brass alloy, pouring it into a mold, and shaping it to our specifications. Zinc and copper primarily compose this alloy, but its unique properties make it an excellent choice for casting. Brass casting allows us to produce intricate shapes and designs, resulting in components that are both functional as well as aesthetically pleasing.

Brass casting is a crucial component in manufacturing because it produces complex parts with high accuracy and consistency. This process is essential in many industries and has become a part of modern life.

Brass casting is used in the automotive industry to produce durable, reliable parts that can withstand road rigors. Brass parts are lightweight and robust, which makes them ideal for the aerospace industry. This contributes to safer and more efficient flights. Brass casting is also used in art and decor to create intricate sculptures, decorative pieces, and other items that showcase the material’s elegance and beauty.

We must equip our workers with Personal Protective Equipment for brass casting; this is non-negotiable. Heat-resistant gloves and face shields are essential, as well as long sleeves made of flame-resistant fabric, safety goggles, and clothing with long sleeves. These items of equipment protect against molten metal splashes and intense heat. They also help prevent potential burns. We take responsibility to ensure that everyone in our team knows the importance of wearing PPE correctly and understands its importance very seriously.

Brass casting is a high-temperature process, so fire safety is a priority. In our facilities, we have strategically placed and made fire extinguishers and fire blankets readily accessible for emergencies. We conduct regular fire safety drills to ensure all staff are familiar with emergency procedures.

Brass alloy is a mixture of zinc and copper, with other elements added to improve specific properties. Casting results are directly affected by the type of brass alloy that you select. Yellow brass, composed of about 70% copper and 30% Zinc, is famous for its color. Red brass is a more expensive metal with a higher copper concentration. It’s also known for its high corrosion resistance.

For shaping the brass molten, molds and patterns are essential. The way is created based on the final part design used to make the cavity in the mold. Molds are usually made of sand, ceramic, or both. They must be strong enough to resist the high temperatures of molten brass and capture every detail in the pattern.

We melt the brass alloy after we have set the temperature. In the furnace, the brass is heated slowly in a high-quality crucible. We take our time, ensuring that the brass melts evenly and that there are no cold spots in the final product.

The mold preparation is an essential part of brass casting, and we are meticulous in every aspect. Preparation of the mold is crucial because it determines the final shape, surface finish, and dimensional accuracy. We’ll explore the most important aspects of mold preparation.

The quality of the part is directly affected by the design of the mold. The mold must accurately reflect the dimensions of the final piece and allow for shrinkage when the metal cools. Molds also need gates and risers. These are channels that will enable molten brass into the cavity of the mold and provide additional material to compensate for shrinkage.

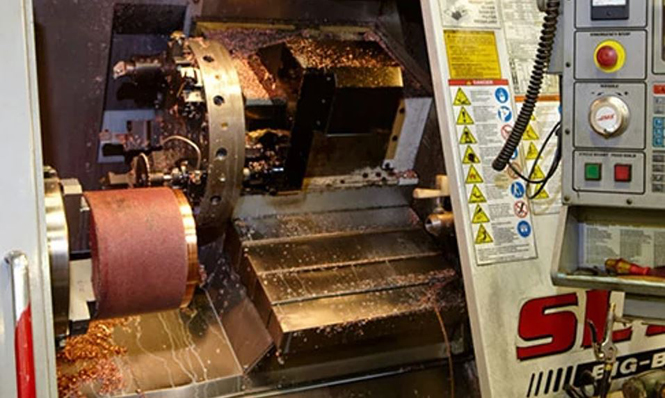

ALUMINUM CASTING

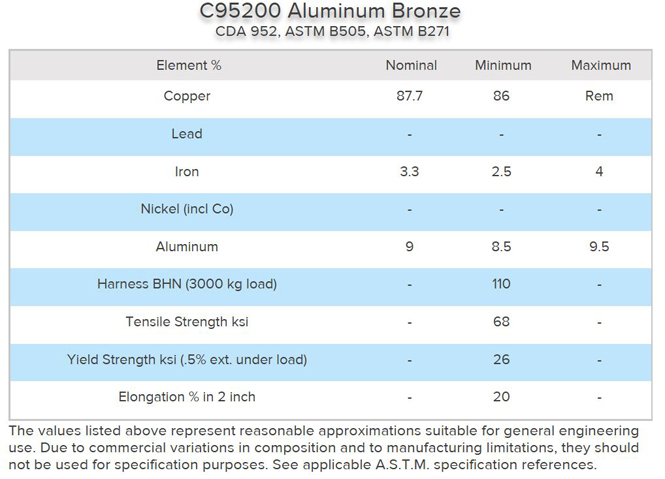

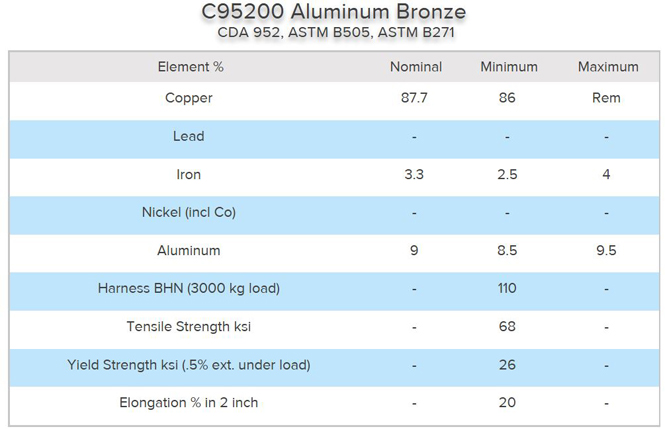

Aluminum Bronze Alloys Aluminum bronze alloys offer superior strength and tarnish resistance. The aluminum component of these alloys forms a protective barrier to prevent corrosion—copper, on its own, is especially susceptible to oxidation and corrosion. Adding resilient aluminum creates the perfect combination of longevity and rich, bronze coloring.

The anti-corrosive properties create high demand for these alloys in water supply applications, as well as any industry where corrosion is a significant concern. You can also use aluminum bronze alloys in welding and casting jobs. We have several choices, such as C63000 aluminum bronze and C64200 aluminum silicon bronze. If you have any questions about our alloys, contact us and we’ll be happy to help.

Aluminum Bronzes have high strengths (comparable to medium-carbon steel), high hardness in the as-cast state, and excellent corrosion resistance properties. They possess good anti-frictional characteristics and resist scaling and oxidation at elevated temperatures. Aluminum Bronzes can be hot worked readily, and some grades possess good cold forming characteristics and respond to a form of precipitation hardening.

Alloy C62300 (CuAl9Fe3) is a binary Aluminum Bronze containing copper, aluminum, and iron. The addition of iron helps grain refining and increases the mechanical strength.

The Aluminum Bronze C62300 is a medium to high strength bronze, which offers the combination of good corrosion resistance in seawater and many acidic environments. It has good ductility, is easily machined, and has wear and anti-galling properties where it finds use in aerospace applications.

As with most copper-based alloys, it also maintains its properties at cryogenic temperatures. The alloy is easily hot worked and can be welded by MIG or TIG joining techniques.

Aluminum Nickel Bronze (CuAl9Fe4Ni4) C63200 is an American Naval alloy with improved corrosion resistance. When the alloy was first produced as a casting, it was found that occasionally the alloy suffered selective corrosion of the kappa phase.

The new wrought alloy has a quench and temper heat treatment which eliminated this problem introducing a structure that changed the morphology of the kappa phase.

The alloy has a proven history within Naval applications where it is used extensively in the building of Nuclear submarines and other Naval surface craft. C63200 can be joined by using MIG or TIG welding techniques.

In addition, the alloy has excellent wear resistance and good corrosion resistance in fresh and seawater.

It is non-sparking which is important in explosive environments, relating to weapon handling, petrochemical industries, and the mining industry.

It has also good erosion/corrosion properties, which find applications for marine propulsion units such as propellers.

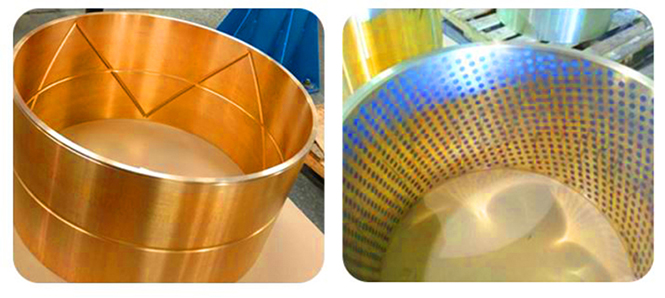

ALUMINUM BRONZE CASTING

Aluminum Bronze Alloy

Aluminum bronze alloys are used for their combination of high strength and excellent corrosion and wear resistance. C95400 aluminum bronze is a popular cast aluminum bronze with high-strength properties and excellent resistance to wear and corrosion. Although this alloy is supplied in the cast condition, it can be heat-treated to enhance its mechanical properties for more demanding applications.

Applications for Aluminum Bronze

Aluminum bronze alloys are used in marine hardware, shafts, and pump and valve components for handling seawater, sour mine waters, non-oxidizing acids, and industrial process fluids. They are also used in applications such as heavy duty sleeve bearings and machine tool ways. Aluminum bronze castings have exceptional corrosion resistance, high strength, toughness, and wear resistance. Not to mention their good casting and welding characteristics.

Aluminum Bronze Alloy Product Selection

NFL14706 Aluminum Bronze Copper Nickel Aluminum, 2.0978, DIN 17665, UA11N, CuAl11Ni5Fe5

NFL14706 is an excellent choice for its application on aeronautical industry, due to its high mechanical properties and oxidation resistance. NFL14706 is resistant to corrosion in saline mist area.

Typical Uses for NFL14706 Aircraft Bronze:

AEROSPACE: Landing Gear Bushings & Bearings, Guides, Nuts

HEAVY INDUSTRY: Civil engineering, iron and steel industry, manufacturing guides, rolling mills

C95900 Aluminum Bronze is characterized by its high strength and excellent corrosion resistance. This alloy is for heavier loads under abrasive conditions where impact is present. C95900 is an excellent heavy duty bearing alloy, and should be used against hardened steel shafts, with both shaft and bearing machined to fine surface finishes.

Uses for CDA 959åÊis utilized in the tool and die and roll forming industries, and its applications include a variety of heavy duty mechanical and structural products including gears, worm drives, valve guides and seats.

C95400 Aluminum Bronze, also known by C954, is the most popular, all purpose aluminum bronze alloy. It provides high yield and tensile strength, good ductility, weldability and exceptional resistance to wear, fatigue and deformation under shock or overload.

Typical applications include bearings, gears, valve components, wearplate and wearstrip. Conforms to continuous cast specification ASTM B505 and centrifugal cast specification ASTM B271.

C61800 is an aluminum bronze containing nominally 89% copper, 10% aluminum and 1% iron. It has moderate strength, moderate ductility and can be hot worked or cold worked successfully. It has good resistance to corrosion in many environments.

Its numerous uses include bushings, bearings, corrosion-resistant components and welding rod